- US-based company Tooling & Equipment International (TEI) expands additive manufacturing capacity with third VX4000 3D sand printer

- As a supplier to General Motors, TEI is using the world's largest 3D sand printer to produce cast cores for the series production of large-format, weight-saving structural components for the Cadillac CELESTIQ

- Each VX4000 prints hundreds of inner cores for several vehicle sets in just one night: making short delivery times for weight and design-optimized components possible

voxeljet AG (NASDAQ: VJET) (the “Company”, “voxeljet”, or “we”), a provider of high-speed, large-format 3D printers and on-demand parts services to industrial and commercial customers and Tooling & Equipment International (TEI), one of the largest users of 3D sand printing in the US, expand their collaboration: TEI has purchased its third VX4000 3D printer.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20230228005066/en/

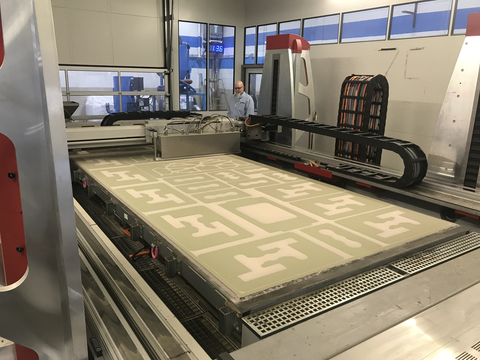

Tooling & Equipment International (TEI), one of the largest US users of 3D sand printing, is expanding its additive manufacturing capacity with the third VX4000 3D printer from voxeljet. (Photo: Business Wire)

As a supplier to General Motors, TEI is using the world's largest 3D sand printer to produce cast cores for the series production of large-format, weight-saving structural components for the Cadillac CELESTIQ. By implementing 3D printing in the development and construction of the components, OEM manufacturers can realize completely new, function-optimized designs. Suppliers benefit from the fast and flexible integration of 3D printed cores into existing production lines.

TEI, an expert in highly complex castings for the engineering and manufacturing industry, has been working with voxeljet since 2018. What started with a three-year volume contract of over 500,000 liters of 3D-printed sand turned into a success story for both companies. TEI is the only company in the US to own three of voxeljet's VX4000 3D printers, which are among the world's largest 3D sand printers with a build volume of 4 x 2 x 1 meters. With its third VX4000, TEI has now expanded its additive manufacturing capacity to up to 2.5 million liters per year. This enables the US company to implement further technically demanding projects such as the series production of lightweight components for the underbody structure of the all-electric Cadillac CELESTIQ.

Each casting replaces up to 40 components

The novel underbody structure consists of six large precision sand-cast aluminum parts. In order to realize the complex structures as economically and lightly as possible, TEI uses additive manufacturing in production for all inner cores. This allows stiffening features to be incorporated into the hollow sections, which is not economically feasible with conventional manufacturing. A total of 51 additively manufactured sand cores are used in the production of each vehicle underbody. TEI prints these using the VX4000 printers, each of which prints hundreds of inner cores for several vehicle sets in just one night. After printing, the cores are smoothed, coated with a fireproof coating, placed in sand molds and finally cast using a low-pressure filling process. Each of the six castings reduces the number of parts by 30 to 40 components compared to a typical stamped construction. As each structural part has fully machined interfaces, the six castings can be assembled precisely and very tight tolerances can be maintained for assembly fabrication.

Short delivery times for weight and design-optimized lightweight components

Large-format mold and core printing on the VX4000 3D printers makes production leaner and therefore faster and more economical compared to conventional manufacturing. Significantly fewer components need to be produced, which simplifies and speeds up assembly work. "By eliminating tools and taking advantage of the large build volume of the VX4000 printers, we can significantly reduce delivery times and produce lightweight components with optimized topologies. This would not be possible in the conventional way," explains Oliver Johnson, President of TEI. In addition, 3D sand printing makes completely new designs and lightweight structures possible. This results in geometrically optimized parts, which are very important for the automotive and aerospace industries. What is important for the implementation at suppliers: New function-optimized designs can be realized quickly and flexibly with the VX4000 3D printers and printed cores can be easily integrated into an existing production.

"We are pleased to have TEI as a strong partner and user of sand 3D printing in the US. The purchase of the third VX4000 printer builds on previous system installations at TEI's corporate site in Livonia, Michigan, and enables the company to grow rapidly and deliver unique projects like this," said Michael Dougherty, Managing Director at voxeljet America Inc. "Together, we will further establish additive manufacturing technology in industrial manufacturing and intensify our collaboration. We are proud to support the company with our unique 3D printing technology and to show once again that our printed casting technology is entering production and enabling unprecedented designs.

About voxeljet

voxeljet is a leading provider of high-speed, large-format 3D printers and on-demand parts services to industrial and commercial customers. The Company’s 3D printers employ a powder binding, additive manufacturing technology to produce parts using various material sets, which consist of particulate materials and proprietary chemical binding agents. The Company provides its 3D printers and on-demand parts services to industrial and commercial customers serving the automotive, aerospace, film and entertainment, art and architecture, engineering and consumer product end markets. For more information, visit http://www.voxeljet.de/en/.

About TEI:

TEI is a global leader in the design, engineering and manufacturing of prototype, pre-production and mass production equipment for the casting industry. TEI products are the highest quality and are backed by a reputation for innovation, design excellence, and precise first-run performance. TEI is a full service, vertically integrated supplier offering a complete range of services in Engineering, Tooling, Casting, Machining and Inspection complete on one site. This approach delivers TEI and its customers’ fundamental advantages in terms of timing, confidentiality, and quality.

Cautionary Statement on Forward-Looking Statements

This press release contains forward-looking statements concerning our business, operations and financial performance. Any statements that are not of historical facts may be deemed to be forward-looking statements. You can identify these forward-looking statements by words such as ‘‘believes,’’ ‘‘estimates,’’ ‘‘anticipates,’’ ‘‘expects,’’ ‘‘projects,’’ ‘‘plans,’’ ‘‘intends,’’ ‘‘may,’’ ‘‘could,’’ ‘‘might,’’ ‘‘will,’’ ‘‘should,’’ ‘‘aims,’’ or other similar expressions that convey uncertainty of future events or outcomes. Forward-looking statements include statements regarding our intentions, beliefs, assumptions, projections, outlook, analyses or current expectations concerning, among other things, the projected timing and successful completion of the sale-leaseback transaction, our results of operations, financial condition and business outlook, the industry in which we operate and the trends that may affect the industry or us. Although we believe that we have a reasonable basis for each forward-looking statement contained in this press release, we caution you that forward-looking statements are not guarantees of future performance. All of our forward-looking statements are subject to known and unknown risks, uncertainties and other factors that are in some cases beyond our control and that may cause our actual results to differ materially from our expectations, including those risks identified under the caption “Risk Factors” in the Company’s Annual Report on Form 20-F and in other reports the Company files with the U.S. Securities and Exchange Commission. Except as required by law, the Company undertakes no obligation to publicly update any forward-looking statements for any reason after the date of this press release whether as a result of new information, future events or otherwise.

View source version on businesswire.com: https://www.businesswire.com/news/home/20230228005066/en/

Contacts

Investors and Media

Johannes Pesch

Director Investor Relations and Business Development

johannes.pesch@voxeljet.de

Office: +49 821 7483172

Mobile: +49 176 45398316